- Shanghai Zhongshen International Trade Co., Ltd. - Two decades of trade agency expertise.

- Service Hotline: 139 1787 2118

Contents

ToggleMachineryEquipment ImportsThe "last mile" challenge

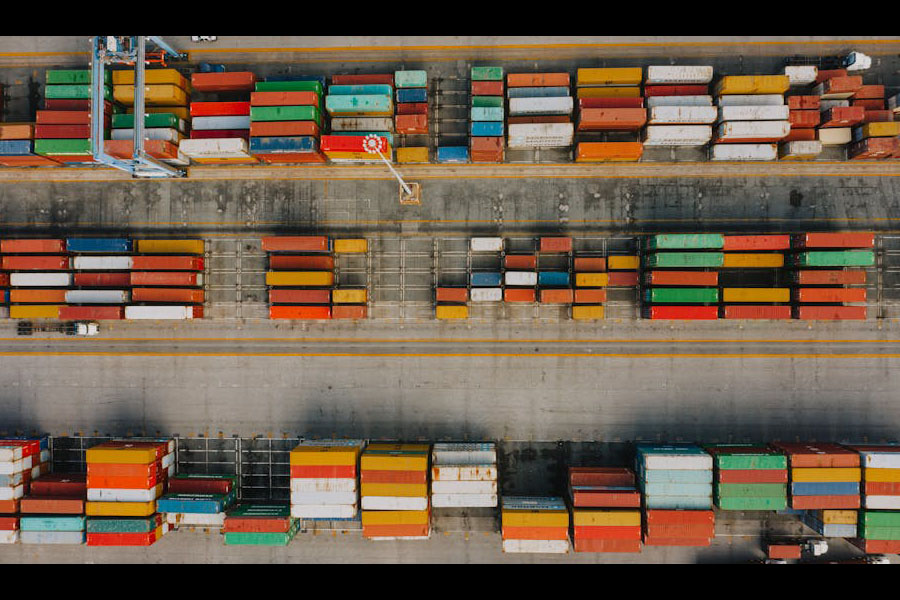

In the field of international trade, the import of mechanical equipment has always been regarded as a "hard nut to crack." According to customs statistics, in 2022, China's import value of mechanical equipment reached 2.4 trillion yuan, with filling equipment accounting for approximately 8%. However, many importers often encounter the "last mile" challenge under EXW terms—the complex process from picking up goods at foreign factories to final domestic delivery.

As a professional agency with 16 years of practical experience, we have handled import cases for hundreds of filling machines. Today, we will share a one-stop EXW door-to-door solution using German BOSCH filling machines (HS Code: 84223010) as an example.

Three key preparations for filling machine imports

Documentation compliance check

Unlike ordinary goods, special attention is required for filling machine imports:

- Original factory invoices must show equipment serial numbers and technical parameters

- Packing lists must indicate IPPC marks for wooden packaging (declaration required if no wooden packaging)

- Import license for electromechanical products (required for some models)

Accurate HS code classification

Tariff differences for filling machines can reach 10%:

| HS Code | Product description | Tariff | Value - added Tax |

|---|---|---|---|

| 84223010 | Beverage filling equipment | 8% | 13% |

| 84223090 | Other filling equipment | 10% | 13% |

Transportation plan optimization

We once helped a Shanghai client save 23% on logistics costs:

- Using 40HQ containers (can hold 2 standard filling machines)

- Direct shipping route from Hamburg Port to Yangshan Port

- Leverage the "advance declaration" policy in the free trade zone to shorten customs clearance time.

EXW door-to-door process breakdown

Phase 1: Pre-shipment preparation (3-5 working days)

- On-site inspection (to avoid disputes over transportation damage)

- Prepare export country documents (e.g. EUR.1 for Germany)It is recommended to verify through the following methods:Trade dispute settlement mechanisms

- Book special containers (some filling machines require open-top containers)

Phase 2: International transportation (Maritime TransportationApproximately 30 days)

- Under EXW terms, arrangements required:

- Factory pickup (need to confirm loading/unloading conditions in advance)

- Export Clearance(Note EU REACH regulation)

- Marine insurance (recommend All Risks coverage)

Phase 3: Domestic customs clearance (3-7 working days)

Key points to note:

- 3CCertification exemption (industrial equipment usually exempt)

- Used equipment requires CCIC inspection certificate

- Customs valuation may require payment evidence

Pitfall Guide: The "Landmines" We've Stepped On

Case 1: Cargo detained due to document discrepancy

A client provided technical specifications that didnt match the actual goods, resulting in 7-day customs detention. Solution: We now require clients to provide equipment nameplate photos for advance verification.

Case 2: Wood packaging violation

Untreated wooden pallets resulted in fumigation costs of 12,000 yuan. Now we strictly enforce the "triple-check" system: factory self-inspection + agent re-inspection + port sampling inspection.

Case 3: HS code dispute

Clients self-classification error caused 180,000 RMB overpayment. Through our professional pre-classification service, we successfully applied for tax refund.

Why choose professional agents?

According to our statistics, professional agents can bring clients:

- 40% shorter clearance time (average 5.8 days → 3.5 days)

- 15-25% lower overall costs

- Inspection rate reduced from 12% to 6%

Especially under new policies like RCEP, professional agents can help you:

- Utilize rules of origin for tariff benefits

- Plan the "Consolidated Declaration for Split Shipments" model in the free trade zone.

- Handle value-added services like AEO certification

Is your filling machine import ready?

Machinery and equipment importation is a systematic project where each step may affect the final cost and timeline. We recommend importers to:

- Start preparations 3 months in advance

- Reserve 10% of the budget for unexpected situations

- Choose an agent with experience in handling similar equipment

To obtain a customized import plan for your specific equipment, our customs experts can provide:

- Free HS code pre-classification

- Tariff and VAT calculation

- Customized Logistics Solutions

Related Recommendations

? 2025. All Rights Reserved. Shanghai ICP No. 2023007705-2  PSB Record: Shanghai No.31011502009912

PSB Record: Shanghai No.31011502009912